How To Clean An M1 Garand

Cleaning your M1 Garand Barrel and Gas Organisation

Your M1 Garand should be cleaned periodically to forestall corrosion and to ensure the proper operation of your M1. When fouling becomes excessive the accurateness potential of the rifle will begin to degrade. We recommend cleaning every 300 rounds fired or when the rifle is not going to exist in service for more than two days.

If you are shooting corrosive ammunition the burglarize must be cleaned immediately afterward shooting has been completed. For cleaning corrosive ammunition see the department at the end of the article.

Before start, verify that your M1 is unloaded by pulling the op-rod handle fully back and inspecting the chamber!

Getting Started:

There is virtually an unlimited number of tools to choose from when cleaning your burglarize. Hundreds of cleaning kits and solvents are available at your local gun stores and websites. We'll be presenting 1 cleaning method that we feel is the easiest to employ. This method is easy to utilise and protects the accuracy potential of your rifle.

Avoid breaking downwards the rifle and field stripping it unless you absolutely must do and then. The process of disassembling the action on the burglarize degrades its accuracy. For this reason, we merely field-strip our M1 Garands at most in one case a season. During this fourth dimension all the internal areas are cleaned of grease and oil and fresh lubricants are practical.

The Tools:

Our cleaning kit of choice is fabricated by OTIS. Their .30 quotient cleaning kit is the perfect compact tool for cleaning your M1 Rifle. Because of the pattern of the burglarize, a cablevision-based cleaning organization is ideal for use in the M1 rifle.

A pull through cablevision system moves fouling from the breech to the muzzle improving cleaning efficiency. A cablevision based arrangement is besides much faster and user-friendly to employ. Unlike a bolt gun the the M1 has the follower and commodities in the way which makes using a cleaning rod difficult.

The solvent that comes with the OTIS kit isn't the all-time in our stance. Its power to remove powder fouling is average and it has no copper removing capability. Information technology's good to keep the tube with the kit when needed in the field. However, a quality solvent should be purchased for regular cleaning duty.

We've recently created a new gun cleaning solvent after years of formulation and testing. Bore Star, our new product easily outperforms all other brands in both copper removal rates and power fouling removal. Diameter Star is scent-gratis and works will all firearm types. When coupled with the OTIS cleaning organisation this pair of products makes cleaning your M1 rifle a simple task. Be sure to pick upward a canteen of gun oil as well. A little bottle of oil should last you several years or more.

Always vesture protective gloves on your hands when working with solvents.

The last item you'll want to larn is a good set of nylon bore brushes. Because our solvent is designed to dissolve copper nosotros cannot apply statuary or brass cleaning brushes. These brushes volition rapidly break downwards and leave a fake-color behind. This false-color will transfer to the cleaning patch and make it look like your barrel has copper fouling when it may non.

Our brush of selection is fabricated by Montana 10-Treme. Their Heavy Duty Rifle bore castor should final you lot several years and is quite affordable.

The Process:

1If yous have a gun vice or cradle, place the M1 upright with the bolt locked dorsum. If you don't have a cradle, lay the M1 on its side on a table or bench with the operating rod handle facing up. Get your OTIS kit out with a few patches. Install the slotted tip on one end of the cable and screw in the obstruction remover on the other end.

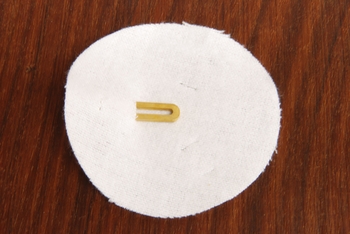

twoThe OTIS system uses a circular patch that has several slots cut in the patch. This system allows you to employ a patch several times before beingness discarded. Commencement by sliding the slotted tip through a patch as shown beneath.

3Pinch the patch as shown beneath and push the folded section in the pinch through the slot on the finish of the slotted tip.

4At present grab the patch and pull it toward the end of the slotted tip locking it in place. When washed correctly your patch should wait similar the image below.

5If the slotted tip isn't nonetheless attached to the cleaning cable, practise so now. Utilise cleaning solvent to the small end of the patch until it's saturated well-nigh an inch up the patch. Slowly Slide the opposite end of the cable into the bore and feed it through the barrel until it exits at the muzzle. Information technology should look equally shown beneath as the patch enters the chamber.

6When the patch enters the sleeping accommodation, terminate pulling on the cable and rotate information technology several times clockwise. This will spin the patch in the chamber, cleaning it.

7Slowly pull the patch through the bedroom until information technology exits the muzzle. Pull the patch off the slotted tip. Flip the patch over and insert the slotted tip into a new slot on the patch. Add together additional solvent to the patch and pull it through the barrel again.

Nosotros find that the OTIS patch is normally good for three uses before existence discarded. Each fourth dimension the patch is used, flip information technology and insert the slotted tip into a new slot in the patch and add solvent. OTIS states that the patch is practiced for six uses just we notice that three is all yous will get earlier the patch becomes as well muddy for further use.

8After you take pulled 2 patches (3 times per patch) through the rifle, replace the slotted tip with the nylon bore castor. Apply some solvent to the brush and pull it through the barrel three times. The brush is non needed after this step. Clean the brush to remove whatever fouling or contagion that may exist left on it earlier putting it away.

Wrapping a pocket-size 1″x1″ patch with solvent effectually the brush can be constructive at removing stubborn carbon deposits.

ixInstall the slotted tip back on the cablevision and install a new patch. At this point, you may discover that the powder fouling has decreased or stopped completely and the patches are first to bear witness some color. The bluish on the patch is from the copper in the barrel. When the patches begin to prove more copper color (blue) and less powder fouling, extend the time between patches. This allows the solvent time to dissolve the copper in the butt.

when only copper fouling remains, await for a few minutes before pulling a fresh wet patch through the barrel. Let the solvent do the work hither. You do not need to scrub out the fouling. The chemical process is doing the hard work for you.

tenWhen a fresh wet patch is pulled through the barrel and no more than color is nowadays, yous're done cleaning. Remember that bronze tips and brushes can add some false color to the patch so don't confuse this with copper deposits from the barrel. At present pull a dry out patch through the butt to remove any solvent left behind.

xiCease cleaning the butt by taking a make clean patch and applying some Gun Oil to the patch. Apply approximately vi to 8 drops to the patch and pull it through the barrel several times. The Gun oil will protect the metal surface of the barrel from corrosion.

The Gas Cylinder:

The gas cylinder on the M1 Garand does not need to be cleaned after every outing. The gas cylinder is stainless steel and won't rust. Nosotros recommend cleaning every 500 rounds fired or when the rifle is not going to be in service for more than than a week. Practice non remove the gas cylinder from the barrel if possible. Doing so will hurt the accuracy potential of the burglarize. The gas cylinder tin be cleaned with the rifle assembled. You do not demand to field strip the burglarize to clean the gas cylinder.

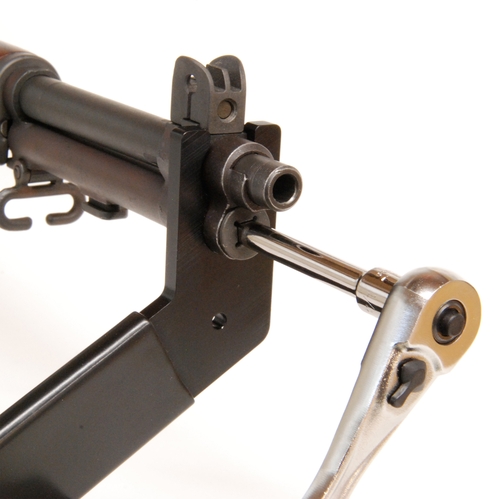

1Using a Gas cylinder wrench or a padded vice, back up the gas cylinder, and using an appropriate tool for the blazon of gas plug you take, unscrew the gas plug from the gas cylinder. The plug tin be very tight.

A 1/four″ socket extension fits nicely in the gas plug. This allows you to employ a socket commuter to loosen and tighten the gas plug. The older unmarried slot type of plug will crave a large standard screwdriver or the use of the combination tool.

2 With the gas plug removed, pull back the operating rod and lock the bolt open. This retracts the operating rod piston and allows us access to the inside of the gas cylinder. Take a .45 Caliber diameter brush and wrap a patch around it. Apply solvent to the patch until saturated. Scrub the inside of the gas cylinder with the brush/patch several times. Flip the patch and echo. Continue until all the powder fouling has been removed.

The gas piston and the last 1″ of the gas cylinder that is non attainable practise not require frequent cleaning. These areas can be cleaned during the yearly maintenance cycle. The power stroke occurs in the first half-inch to an inch of the gas cylinder closest to the gas plug. During the power stroke, Gas blows by the piston and exits out the rear of the gas cylinder.

iiiMake clean the gas plug and the op-rod where it tracks nether the front manus-guard. The gas escaping from the gas cylinder will go out fouling on the op-rod here and oftentimes on the sling. This is normal.

4 The gas cylinder can be left dry out or a few drops of oil tin exist applied to the inside surface. Any excess oil or grease in the gas cylinder will be blown out after the first shot. Add a few drops of gun oil to a patch and oil the inside of the gas cylinder. We find that this makes future cleaning easier.

5 With the gas cylinder supported, torque the gas plug on to 10 Ft-Lbs. A drib of oil tin be applied to the threads of the gas plug. Friction between the threads is not what makes a bolt or gas plug tight. Commodities stretch is what applies the clamping force. In the instance of the gas plug, the flange that makes contact with the gas cylinder applies the holding strength. Keep the flange and the mating surface on the gas cylinder dry.

6Stop upwards by cleaning the bolt face up, follower, and any fouling present in the receiver. When finished, re-apply grease to whatsoever of the required surfaces that need it. Yous can see the grease locations by post-obit this link. [Greasing your M1 Garand Link]

Corrosive Ammunition:

Westwardhat exactly is corrosive ammunition? Many shooters today take heard of corrosive armament but probably have never seen or shot any. The word corrosive conjures a mental epitome of acids or other evil substances that want to dissolve your rifle. Thankfully, in this case, the offending corrosive amanuensis is only table salt; Potassium Chloride.

This salt doesn't come from the gunpowder in the ammunition. Rather, it comes from the primer. The salt is the issue of potassium chlorate (The priming amanuensis) decomposing into KCL (Potassium chloride) a salt. As a general rule ammunition made afterwards 1954 will not exist corrosive. There are exceptions, of class.

So how does this salt cause rust in my burglarize? KCL by itself does not cause rust. It'south hygroscopic; meaning information technology takes upwards h2o and holds information technology. That water reacts with the steel(atomic number 26) producing a very pocket-sized electrical current that breaks the water into hydrogen and oxygen. The free oxygen goes afterwards the iron-producing rust. The KCL adds more ions to the solution which increases the electric current catamenia and the rusting process.

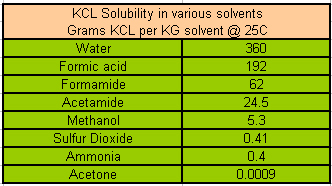

Because the process generates oxygen, putting a coating of oil over the problem does not stop the rusting process. It may dull it slightly, only it doesn't eliminate it. The but way to prevent rust is to remove the KCL. To exercise that we desire to dissolve the common salt in a solution and wash it out of the rifle. The nautical chart below shows which solvents are the most effective at dissolving KCL. The obvious winner is evidently water. The hotter the better.

Windex is often mentioned as a proficient cleaning agent after shooting corrosive ammunition. If nosotros await at the ingredients in Windex nosotros find the following: Isopropanol,2-Butoxy ethanol,Ethylene glycol n-hexyl ether,Water, Ammonia and other surfactants. The only ingredient with whatsoever ability to remove KCL is the water component which is the fourth ingredient in the listing. The h2o component tin can remove KCL, but the solution as a whole is not every bit good every bit water by itself.

Cleaning after using Corrosive Ammunition:

1Offset the cleaning procedure the aforementioned as shown to a higher place. Make clean the rifle until all the pulverisation and copper fouling have been removed. Clean the gas cylinder as described above and identify a paper towel or make clean patch inside the gas cylinder past the gas port. This is to keep water from running down the gas cylinder. Practice not oil the barrel or gas cylinder nevertheless.

iiFill up a small h2o bottle with hot water. With the barrel pointing downwards toward the ground with a slight angle begin to slowly pour the hot water into the breach and let it flow out of the barrel. Pour at a rate such that the water contacts all surfaces within the barrel as information technology runs down its length.

3Repeat the h2o flush one boosted time with hot water. When finished be certain to completely dry any spilled h2o in the receiver and run several dry out patches through the barrel and gas cylinder until all the water has been removed. The employ of a water-displacing oil can exist helpful at removing any water that's in between the gas cylinder and the barrel.

4Be sure to oil all the surfaces that came in contact with the water. Inspect the rifle later 24 hours for any signs of rust. If present repeat the flushing process and oil the parts once again. Make clean the bolt face well and watch for signs of rust over the next week.

5Launder all your cleaning brushes, slotted tips, and cables in hot h2o when finished to eliminate any Potassium Chloride that might be on them.

Welcome to our new website. Returning customers will need to create a new account when checking out or use the invitee checkout option. -Eric Dismiss

Source: https://www.garandgear.com/m1-garand-barrel-cleaning/

0 Response to "How To Clean An M1 Garand"

Post a Comment